Product Overview

MVP Industrial Pump Series

ADVANTAGES to the MVP Series:

- Designed to meet high-pressure demand

- Stainless steel impellers, column, and shaft for long life

- Pressures up to 326 PSI

- Flows up to 28 GPM

- Pulsation-free coolant delivery

- Mount either horizontal or vertical

- Six models to provide progressively higher flow rates and head pressures

- Can be combined with tanks to provide a complete, ready-to-install pumping system

Click HERE for our Build-A-System Brochure!

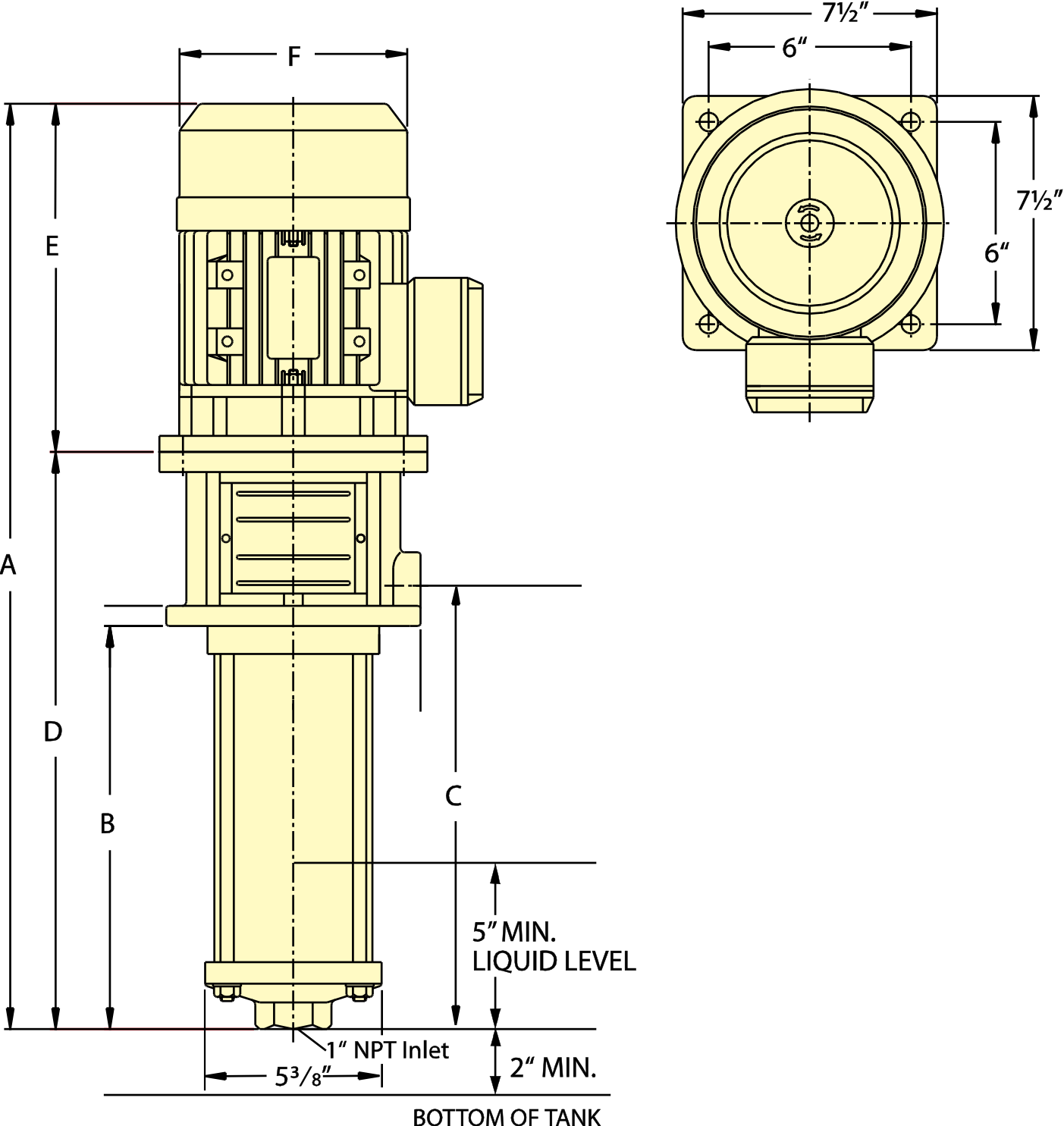

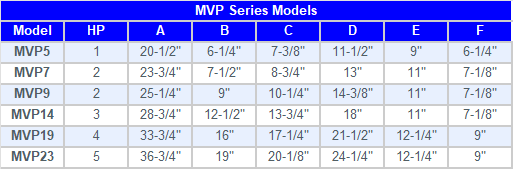

Specifications

Most pumps are available as pump/tank combinations.

MVP5: 1 HP, 3450 RPM, 1" NPT horizontal discharge above integral mounting flange, Maximum discharge pressure 65 PSI

MVP7: 2 HP, 3450 RPM, 1" NPT horizontal discharge above integral mounting flange, Maximum discharge pressure 95 PSI

MVP9: 2 HP, 3450 RPM, 1" NPT horizontal discharge above integral mounting flange, Maximum discharge pressure 120 PSI

MVP14: 3 HP, 3450 RPM, 1" NPT horizontal discharge above integral mounting flange, Maximum discharge pressure 190 PSI

MVP19: 4 HP, 3450 RPM, 1" NPT horizontal discharge above integral mounting flange, Maximum discharge pressure 250 PSI

MVP23: 5 HP, 3450 RPM, 1" NPT horizontal discharge above integral mounting flange, Maximum discharge pressure 326 PSI

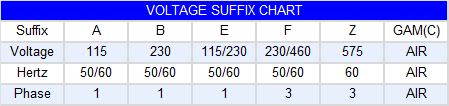

All Models: Operate on 230-460V, 3-Phase Power

Materials

Discharge Head and Frame: Cast Iron

Shaft: Stainless Steel

Bowl: Stainless Steel

Column: Stainless Steel

Impeller/Diffuser: Stainless Steel

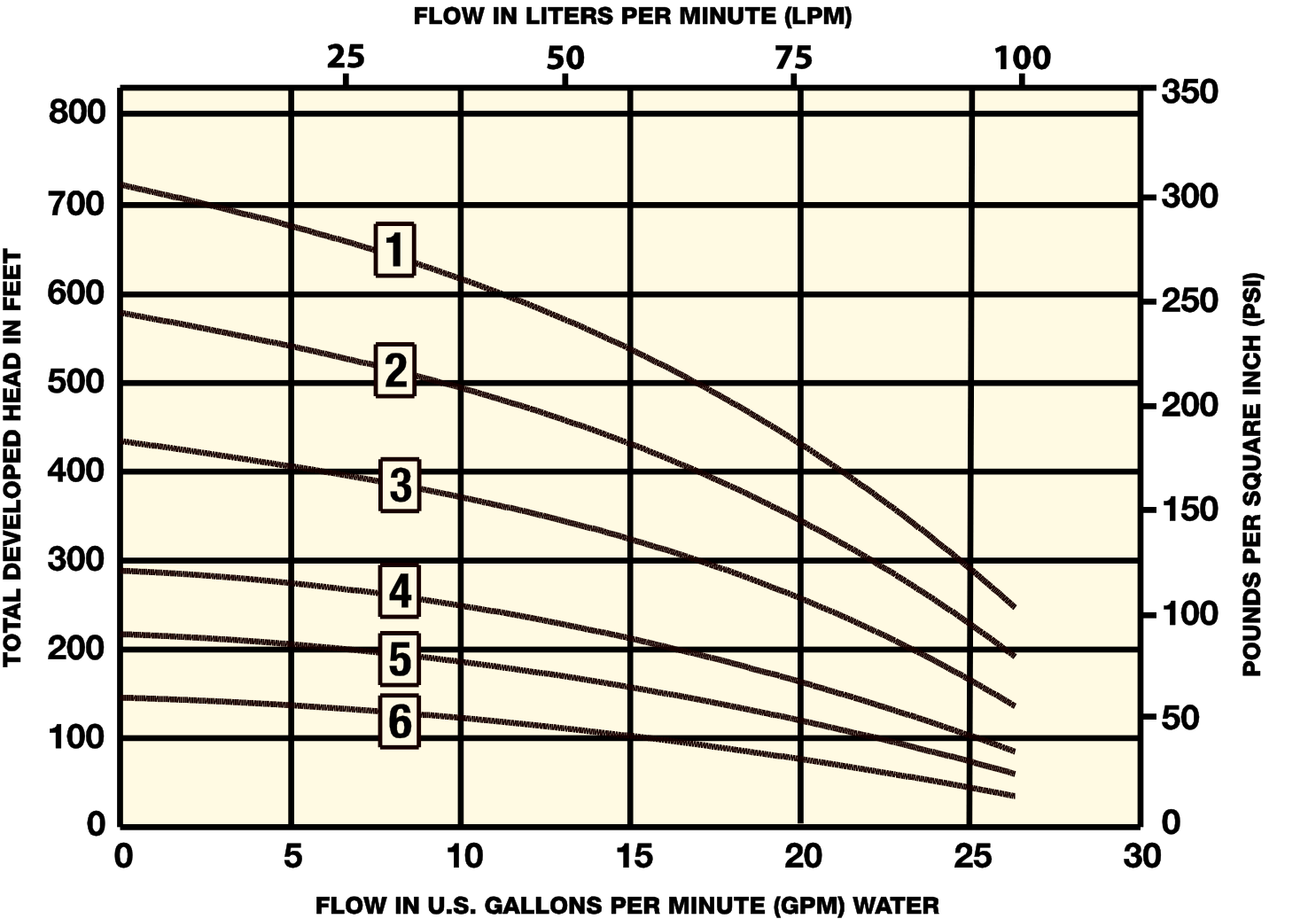

MVP Series Models

1. MVP23 – 326 PSI Max Discharge

2. MVP19 – 250 PSI Max Discharge

3. MVP14 – 190 PSI Max Discharge

4. MVP9 – 120 PSI Max Discharge

5. MVP7 – 95 PSI Max Discharge

6. MVP5 – 65 PSI Max Discharge